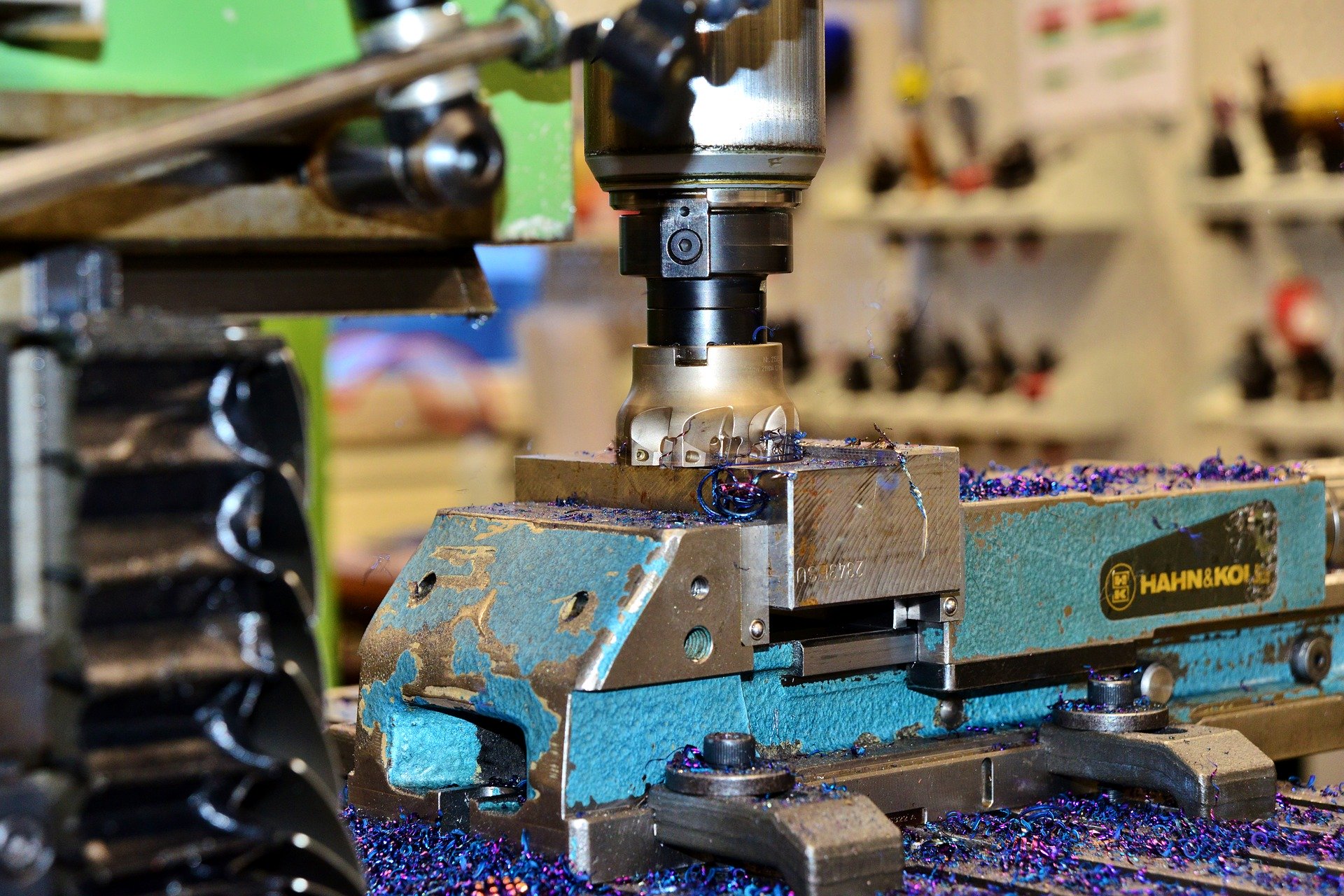

Mechanical and electrical assembly and piping

Installation of industrial production lines, from on-site acceptance of machines to commissioning.

Work carried out on the basis of drawings supplied by manufacturers.

- Mechanical assembly: linking the various production line blocks - blowing, filling, conveying and packaging

- Electrical assembly: wiring, connection and start-up tests (I/O)

- Piping assembly: including welding of piping linking the various machines on the production lines

Support for different machines, for all production capacities and speeds:

- PET container blow-moulding machines

- Fillers for cans, PET bottles and single-use or reusable glass bottles

- Machines for labelling, wrapping and packaging on pallets

- Depalletisers, palletisers and unpackers, case packers

- Conveyors for bottles, bundles, pallets, etc.

- CIP and blenders

- Water treatment and filtration

In collaboration with the manufacturers, our field service engineers handle the transfer of a complete or partial line from one site to another. During transfers, existing machines are upgraded to maintain or improve the overall efficiency of the line.